Though the name Krone may not be familiar to you, the Spelle, Germany manufacturer has been around for over 100 years growing from a simple blacksmith shop to a world leader in forage harvesting equipment. Now run by a fourth generation of the Krone family, the company’s focus continues to be on building the highest quality and most efficient hay and forage equipment.

Krone BiGPack balers are a family of three heavy duty models (890, 1270 and 1290) with configuration options that tailor their operation to your exact needs. The 1270 variants are the BiGPack 1270, BiGPack 1270 X-Cut, BiGPack 1270 MultiBale and BiGPack 1270 X-Cut MultiBale. Our subject of interest for this week’s review is Krone’s multifunction BiGPack 1270 X-Cut MultiBale, which produces rock solid 3’-11” x 2’4” bales up to 8’10” long. But handling huge bales in the field and handling huge bales on the farm are two very different things. The BiGPack 1270 X-Cut MultiBaler addresses the farm handling issue by allowing up to nine more easily handled individual bales to be formed within one large field bale.

|

Using chainless drives, automatic clutches for pre-compression, heavy-duty flywheels that are less prone to vibration and can be driven with less horsepower, compressed air to clean knotters and tandem wheel running gear, BiGPack balers are designed to be productive. Awarded a Silver Medal by the German Agricultural Society (DLG) in recognition of benefits to the farming world that include increased workrate and enhanced operational reliability, BiGPack balers employ many cutting-edge technologies which we’ll touch on below and are ideally suited for the needs of large commercial straw, hay and silage operations.

Material Pick-Up

BiGPack balers utilize a wave-shaped tine band design that is able to work up to 30% faster with increased throughput than with a cam-driven design, which require complex cam tracking controls. Quieter and cleaner with reduced wear requiring less maintenance are all hallmarks of the BiGPack EasyFlow pick-up design. The EasyFlow system is protected by a universal shaft with an integrated ratchet clutch, meaning there are no pesky shear bolts to replace.

|

Cutting System

Owners of BiGPack balers can select 16 or 26 knives using knife control, with 16 for 2’-7.5” chamber width and 26 for 3’-11” chamber width. Knives are driven by a 1’10” diameter rotor that runs directly off the main gearbox. Hardox plates achieve scissor-like cuts and eliminate mushing. Knife trays have two knife drawers with either eight or 13 knives. Drawers are lowered hydraulically for removal or to install knives. Drawers can be pulled out for maintenance or to change length with no tools required. Individual knives are spring loaded to protect against the ingestion of foreign objects. And as soon as the foreign object is expelled, the knives spring back into position. Plugged knives are easily cleared by lowering the tray hydraulically.

PreChop

Predominantly used for straw operations, the Krone PreChop option adds 88 rotary knives and two fixed banks operating in a staggered arrangement. The setup defibrates the straw stem so it flows smoothly through the baler and into well-shaped bales that are easy to handle. Great for poultry and dairy cow bedding, the knives rotate at 3000 rpm and are reversible for long service life. Krone PreChop units are easy to remove when not needed – just pull the pin and driveshaft, then lower the unit hydraulically onto the transport wheels.

Varying Conditions

Krone BiGPack balers come with Variable Fill System (VFS) technology. This is a six-phase feed system that makes rock solid well-formed bales even with small windrows and when operated at reduced forward speeds. A cam clutch provides maximum drive protection with maximum uptime and there are no shear bolts to fuss with or inventory. Blockages can be removed without having the driver get out of the tractor cab. To reset the clutch, just lower the PTO speed and the reset takes place automatically.

Knotters

The BiGPack 1270 X-Cut MultiBale comes with six knotters as standard equipment, though double knotters are available as an option suited for wet conditions and extra heavy silage. The 1270 can hold 32 balls of twine (16 on each side), giving a capacity of up to 900 bales without reloading. An onboard compressor supplies air to keep the knotters clean and even comes with an extended hose to blow dust off the BiGPack at the end of the workday. Individual bales are knotted as well as the entire large bale.

Maintenance

BiGPack balers come with an electric lubrication system that automatically greases the pick-up system, VFS components and the knitters – everything but the drivelines, which are lockable for safe service. Onboard hydraulics are self-contained with the pump driven by the main gearbox, preventing any possibility of cross contamination with the tractor hydraulic system.

Maneuverability

Krone engineers have paid attention to the challenges of field and transport. The BiGPack 1270 X-Cut MultiBale comes with pivotal gauge wheels that can be adjusted in height without tools. If equipped with tandem wheels, the tandem axle is steerable (rear wheel steering), and tight quarters become less of an issue for the 30’1” long (26’ transport) x 9’5” tall x 9’10” wide BiGPack 1270 X-Cut MultiBale. Axles are rated for a 31 mph travel speed, so the time between jobs is also reduced.

Options

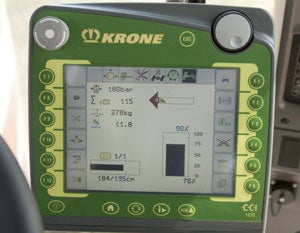

CCI ISOBUS terminals can be specified, though the BiGPack 1270 X-Cut MultiBale comes with a graphical interface (Comfort Control) that monitors and adjusts baling pressure, bale counter and knotters. A CCTV camera, color monitoring screen and moisture sensor with digital readout are among some of the other available options we might select if we were in the market for a large high-speed square baler. Brakes are specific to the requirements of the destination country, but are either two-circuit compressed air or full hydraulic.

North America has become the largest export market for Krone and appropriately its dealer network exceeds 350 with fully-staffed offices in Memphis, Tenn. and Reno, Nev. Warehouse locations are also located north of the border in Ontario and Quebec.

If you’re in the market for a large baler with state of the art technology and with high productivity needs, you may want to check out the Krone BiGPack line up.

Related Reading

John Deere 47″ Two-Stage Snowblower Review

Woods Equipment Co. Subcompact Tractor Attachments

2011 Wallenstein BX32 Chipper Review

2011 Bush Hog 296 Rotary Cutter Review

Your Privacy Choices

Your Privacy Choices