EPA Final Tier 4 (FT4) requirements became a reality in January of 2013. Engines from 20-49 horsepower must now not exceed 5.5 gm/kw-hr. of Carbon Monoxide (CO), a combined 7.5 gm/kw-hr. of Nitrogen Oxide (NOx) plus Non Methane Hydrocarbons (NMHC), and 0.03 gm/kw-hr. Particulate Matter (PM). Engines from 50-74 horsepower cannot exceed 5.0 CO, 4.7 NOx+NMHC, and 0.03 PM. Engines from 75-174 horsepower cannot exceed 5.0 CO, 3.59 (3.4+0.19) NOx+NMHC, and 0.02 PM. And while clean air is beneficial to all, the resultant manufacturer challenges to reduce emissions by 90-95% have been immense.

Most manufacturers have chosen a combination of technologies to achieve these standards. Key technologies include: Diesel Oxidation Catalyst (DOC), Diesel Particulate Filtration (DPF), Selective Catalytic Reduction (SCR), Exhaust Gas Recirculation (EGR) and Closed Crankcase Ventilation (CCV). We covered most of these technologies in January of 2014 but here is a quick refresher of how each work and the plusses and minuses.

DOC

How it works – Exhaust aftertreatment where palladium and platinum catalysts oxidize hydrocarbons and carbon monoxide into carbon dioxide and water.

Plusses – Exhaust is cleaner, does not require regeneration, has limited maintenance requirements, meets emission standards at a lower cost, and no backpressure to monitor.

Minuses – Catalysts are rare earth materials that are expensive.

DPF

How it works – Exhaust aftertreatment where particulate matter is burned off during a regenerative process.

Plusses – Exhaust is cleaner.

Minuses – High heat generation that could ignite a fire in enclosed areas or on dry grass, systems require varying degrees of operator involvement or attention, systems are expected to last 4500-15000 hours, but will contain a hazardous waste and must be replaced with a serialized filter.

SCR

How it works – Diesel Exhaust Fluid (DEF) is injected into the exhaust stream creating a chemical reaction that converts exhaust into nitrogen and water vapor.

Plusses – Exhaust is cleaner.

Minuses – More complex system that requires DEF to be on hand, DEF has shelf and temperature limitations.

EGR

How it works – EGR systems reduce NOx by lowering the oxygen concentration in the combustion chamber as well as through heat absorption.

Plusses – Exhaust is cleaner.

Minuses – Iincreased PM and increased fuel consumption.

CCV

How it works – Captures gasses from the combustion chamber and cleans them before being released into the environment. Similar in function to an automotive PCV valve.

Plusses – Returns engine blow-by back to intake system as a fresh charge to further combustion cycles.

Minuses – Requires some maintenance to be kept clean and open. Oil change intervals are important.

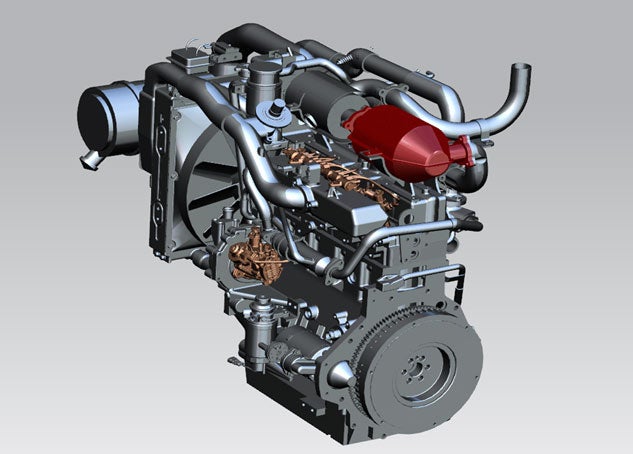

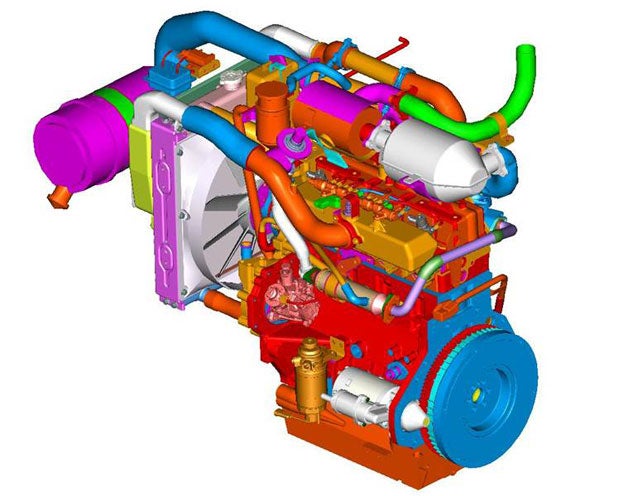

Mahindra’s approach to EPA FT4 requirements (mCRD) began with what would turn out to be a $30 million investment. Involved were major design modifications to the crankcase, crankshaft, connecting rod, piston, flywheel, gear train, cylinder head, and manifolds. A Bosch Common Rail Diesel (CRD) system delivering fuel at 23,000 psi is at the heart of controlling Mahindra engine emissions and greatly reduces engine smoke while delivering the added advantage of decreased sound levels. The mCRD system allows for more efficient fuel combustion through multiple injections per cylinder stroke. For engines above 50 horsepower, a waste gate turbocharger is used along with an air-to-air intercooler.

In conjunction with the CRD performance advantages, Mahindra uses an EGR system with a higher rate of recirculation, a DOC and CCV. mCRD ends up being a simpler solution, with only a $600 tool and any laptop being required by dealers to diagnose the system verses the reports we’ve heard from competing manufacturer dealers of requiring investments of up to $8000 plus additional technician training. And forgoing the DPF route means no excess heat from the DPF blowoff, lesser system complexity, no potential for the DPF to plug up or need replacement, and no requirement for a back pressure sensor.

We had a chance to catch up with Mac Payne, Mahindra’s director – Dealer and Product Development at his Houston, Texas office for the following interview.

Tractor.com – What kind of cost impact did moving to the mCRD system add to Mahindra tractors?

Mac Payne – About 15%, which is on par or better than other manufacturers.

Tractor.com – Was fuel consumption improved or decreased?

Mac Payne – Fuel consumption is on par with Tier III engines.

Tractor.com – Did achieving FT4 emission levels require a detuning of engine horsepowers?

Mac Payne – No.

Tractor.com – Will Mahindra FT4 tractors require a different engine oil?

Mac Payne – Yes, a new class of oil called CJ-4 is a mandatory component of the system.

Tractor.com – What kind of field testing have mCRD engines gone through?

Mac Payne – Mahindra uses heavy duty engines of wet sleeve designs that farmers in India commonly put as much as 1500 hours on each year. This heavy, hard use has proven out the simplicity and reliability of our mCRD technology.

Tractor.com – How has business been?

Mac Payne – Fantastic. Mahindra is up to 450 dealers in the US alone.

Tractor.com – Did you experience a push of Mahindra dealers stocking up on Tier III tractors so as to have the lesser priced, possibly easier to sell models available?

Mac Payne – Mahindra did the same, but now that supply has been exhausted. It’s a reality, but purchasers will have to go to FT4 machines. This is an across-the-board industry reality.

Tractor.com – Has the warranty on FT4 tractors changed?

Mac Payne – No. Mahindra offers a full five-year/3000 hr. warranty on engines.

Tractor.com – Final comments?

Mac Payne – The mCRD technology used in every Mahindra tractor adds to the long-term value of the machine. We hear of fleet truck operators (where DPFs were first employed and where much of the long-term performance and cost history is known) complaining of filters plugging up. Mahindra owners will have no such worries. Operators will not have to worry about when DPF regeneration is taking place. Operators will not have a filter that can plug up and at some point require expensive replacement.

Your Privacy Choices

Your Privacy Choices